|

|

WHAT

MAKES PETRON PLUSTM

FORMULA 7 UNIQUE

First of all, the waste of resources resulting from

high friction and wear were estimated at $194 Billion Dollars by Dr. E.

Rabinowicz, of MIT in the United States alone, and well over $5 Billion

Dollars by the National Research Council's Associate Committee on Tribology

in Canada. The potential savings

offered by improved lubrication and a better understanding of the science

of tribology are correspondingly great.

Is it any wonder that the lubrication of machinery never receives

much consideration and when a serious problem does occur, most people tend

to blame it on the lubricant itself, instead of learning how to recognize

the root cause of the problem.

These shortcomings in the understanding of

lubricants and lubrication have lead many maintenance specialists to make

incorrect and costly assumptions about lubricants and their

application. Furthermore, executive

officers around the world are full of bright ideas, as well as meaningful

engineers and managers who treat the aspect of correct lubrication and the

application of proper tribological techniques, as either unnecessary, too

costly, or both.

These same people mistakenly assume that the

consequences of friction and wear are "normal" and refuse to take

advantage of the huge savings and improved machinery reliability which

could be achieved with the proper lubricants, understanding tribology, and

paying more attention to the problems related to friction, and wear.

The word "Tribology" was introduced in the

1960's to mean the "science and technology of the wear of interacting

surfaces in relative motion and associated subjects and

practices". Tribology

effectively coordinates many technical disciplines, such as chemistry,

metallurgy, machine design, lubrication engineering, etc., for solving

friction and wear problems.

The main cause of wear in engines and other

lubricated systems is abrasion and oil contamination. It is ironic that while engineers and

tradesmen are taught how to design, build, or repair equipment, few are

taught an understanding of the inter-relationship between friction, wear and

lubrication and how to reduce the problems associated with these aspects of

equipment operation.

The above brings us to Petron

PlusTM Formula 7 Products. For

over thirty-four (34) years, Petron PlusTM Formula

7 Products have been markets and provided (through distributors) to the agricultural, aviation,

aerospace, city/states agencies, food/drug mfg., hospitals, hotels/motels

& commercial properties, industrial plants, commercial, mining/quarries

& cement plants, automotive mfg., industrial fleet, Motorsports race

teams, metalworking facilities, oil companies & refineries, pulp &

paper mfg., power plants, printing & publishing, recreation operations,

steel/metal operations, transportation operations, university &

schools, military and government applications around the world.

Today Petron PlusTM Formula 7 has over 450 products with

1,450 sku (part numbers) numbers.

They range from finished synthetic, non-synthetic and partial

synthetic motor oils, ATF's, automotive gear oils, industrial gear oils, hydraulic

fluids, compressor oils, natural gas engine oils, automotive a/c lubes,

turbine oils, refrigeration oils, natural gas compressor oils, aerosol

products, greases, metalworking fluids, to gasoline additives, diesel fuel

additives, industrial cleaning products, and automotive and fleet cooling

systems cleaners and corrosion inhibitors & treatments. We have a full fine of biodegradable

products. Over fifty (50) of these

products have H-1 and H-2 food grade approval by USDA, NSF and/or Kosher approved. Plus a product line that meets certain Military Specifications.

Petron PlusTM Formula 7 is not an oil

additive, nor a replacement petroleum product, but a patented new package of

high-tech petroleum and synthetic constituents chemically bonded together

in a patented new process to form a totally new EP ingredient, The

Petron PlusTM

Formula 7 products are formulated for each individual type of application

(engine oils, automatic transmissions, gear boxes, compressors,

refrigeration systems, metalworking, etc. (not a one product does-all like

some other companies market) which may easily be blended in small

proportions into virtually any standard lubricant currently available.

The Petron PlusTM molecules are very small, 0.1 micron

in size (a human hair is 50 microns).

If you could imagine for a moment ...Solid additives (i.e., PTFE,

Teflon® (a registered trademark of DuPont), Moly,

Graphite, etc.) are 2 to 10 microns in size. This would be how a beach ball would compare to a golf

ball.

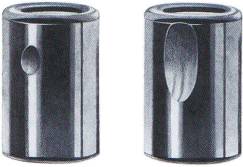

The

Bearing on the right was protected with major brand EP lubricant during

Timken test. When Petron

PlusTM Formula 7 technology was added to the

EP lubricant the bearing on the left showed minimal surface breakdown

at three (3) times the weight.

At

the weight where the EP lubricant stopped the Timken tester, the Timken tester could be

turned on-and-off with a full load on it with the PlusTM Formula 7 added, and showed no increase in amp’s, then with three (3) times

the weight it showed only a slight increase in amp’s.

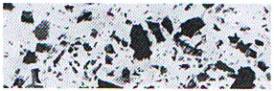

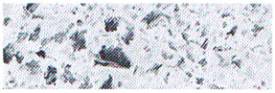

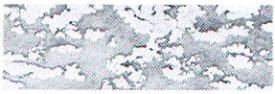

Molybdenum

Disulfide Graphite

Teflonâ (registered Trademark

of DuPont) Petron Plus Formula 7

The above

Micrographs show material structures of Molybdenum Disulfide, Graphite,

Teflon/PTFE, and Petron PlusTM Formula 7. The solid products are 2 to 10 microns in size; Petron PlusTM Formula 7 Nano

Monomolecular technology is 0.1 micron in size.

When Petron PlusTM Formula 7 is added to an existing lubricant,

tiny molecules (less than 1 micron in diameter) are carried directly to the

friction face. Because the

molecules are very small, 0.1 in size (a human hair is 50 microns). Solid additives (i.e., PTFE, Teflon (a

registered trademark of DuPont), Moly, Graphite, etc.) are 2 to 10 microns

in size. The Petron PlusTM Formula 7 technology is

much the size of a cold virus, and in that conjunction can’t be stopped.

Once

the molecules reach the friction face, they are attracted to the surface,

thereby reducing friction, wear and drag..

The Petron PlusTM Formula 7 Nano

Monomolecular technology contains none of the common EP agents such as molybdenum disulfide (Moly),

graphite, Teflon, or PTFE resins, copper, lead, silver, or other metals,

nor other previously used EP agents.

It doesn’t contain Carbon Tetrachloride, 1,1,1, Trichloroethane, or

Chlorinated Paraffin, or Chlorinated Solvents or any other harmful solvent.

The Petron PlusTM Formula 7 Nano

Monomolecular lubricant technology is about to revolutionize the design

and performance of wear components, thanks to the extremely high shear strength

of the re-engineered hydrocarbon.

Once

there, intermolecular force pulls the molecules to the surface where they cluster

to fill in any pores or roughness.

The remaining areas are covered by a layer less than one molecule

deep, hence the term Nano Monomolecular.

The intense shear strength of these

microscopic layers provides outstanding smooth running and reduced friction

characteristics, under the most demanding conditions even the most advanced

EP lubricants fail to meet. To

dispel fear that this new technology is just another ‘snake oil’, the most

demanding tests have been used, and are still used when testing these

products.

PETRON PLUSTM Contains NO

TEFLON®

or PTFE RESINS (like Slick-50, T-Plus, etc.), GRAPHITE, MOLYBDENUM

DISULFIDE (MOLY), COPPER, LEAD,

SILVER or other metals, nor other previously used EP agents, PETRON PLUSTM DOESN'T Contain CARBON TETRACHLORIDE, 1,1,1,

TRICHLOROETHANE, or CHLORINATED PARAFFINS (like Prolong, Dura-Lube, Energy

Release, etc.) or CHLORINATED SOLVENTS or any other harmful solvents.

Application areas in the industrial sector

includes; high power density hydraulic systems, gear boxes in mining,

automotive, commercial vehicles to the largest gear boxes in the world;

mining, construction and manufacturing plants and agricultural equipment;

all types of engines from gasoline, diesel, propane to marine engines; as

well as chains, bearings and other types of mechanized systems, including

major cities, states, and the US government; A test conducted inside the

Tsingtao City Development Zone’s bus company, selected five big buses and

added the new technology to the buses.

Following strict experimental standards the test allowed no

adjustments to the buses. The

results showed “Fuel consumption went from 15 liters before the Petron

PlusTM Formula

7 Products were added

down to 12.14 liters after the Petron PlusTM Formula 7 Products were added. This was a fuel consumption drop of 19%. Five buses following the same testing

procedures and had an average fuel savings of 16.2% and the operating conditions

improved dramatically. Engine noise was cut down; lube

oil consumption dropped 50% and emissions dropped significantly.” In another test in a similar experiment using

a Toyota car, the results they observed showed a “25 liter savings in

fuel consumption

in a drive from Shengyang to Dailin.”

That was a savings of 17.9%.

In applications like these in China, US, and

some of the largest companies in Europe, the new technology has routinely

resulted in improved performance such as 15-20 percent reduction in

temperature, 10-20 percent reduction in power consumption, up to 10 percent

reduction in operating noise and up to 50 percent increase in maintenance

intervals.

A

European tractor manufacture saw between a 10% to 24% reduction in power on a paint shop conveyor after the Petron

PlusTM Formula

7 Product was applied to the

conveyor chain links, lubrication went from once a week to every two weeks. An Automotive Exhaust Manufacture in South

Wales saved £67,401.60 (pounds not dollars) in one year by applying a Petron PlusTM Formula 7 Products to a Cam Follower Bearings in a Silencer Box End

Seamer. The Petron PlusTM Formula 7 Product had extended the bearing

life from one month to three months without failure. A major grain company in the United

States reported a 16% reduction in amp load, and saw a temperature drop after a Petron

PlusTM Formula

7 Products was added to

an elevator gearbox that was over-heating.

A

cement plant in the mid-west region of the U.S. relates its first

application of one of the Petron PlusTM Formula 7 Product when they had a major

failure of its #2 trunnion bearing.

The trunnion shaft was badly cut, the plant manger reported. They had been planning a winter outage,

but it was not scheduled until March.

The trunnion changout would take several days. They took a change. He had the failed bearing replaced, and

left the trunnion, which weights about 50 tons, in place. At which time they added Petron

PlusTM Formula

7 Transmission &

Gearbox Supplement (T&GB) to the high-pressure lube system. The trunnion bearing lasted

until the scheduled outage. The plant manager stated: “you probably can’t

fathom how significant that was, because the scored trunnion shaft and

bearing probably wouldn’t normally have held up for more than several hours

of operation.” When they dismantled the trunnion

assembly, a representative from manufacture was present. He couldn’t believe what he saw. The bearing under the scored

shaft did not have a mark on it.

The

plant maintenance supervisor reported that they have many Falk gearboxes

operating in very dusty environment.

Temperatures can vary considerably from very cool to very hot. He said; they have found that the Petron

PlusTM Formula

7 T&GB improves gear

lubrication, smoothes everything out, and helps us to avoid problems.

For

example, a large Falk gearbox, which drives a roll grinding mill, is about

30 feet long, 14 feet wide and holds 1,050 gallons of gear oil. They filled the gearbox with a mixture

of 85% regular gear oil and 15% of one of the Petron PlusTM Formula 7 T&GB . Almost immediately they saw a decrease in amperage, and

they saved energy, plus the unit’s overall smoothness had improved. Similarly, a critical conveyor is equipped

with another large Falk gearbox.

Before using the Petron PlusTM Formula 7 T&GB, they were having bearing

or a gear problem every two years. Since they began adding the T&GB supplements, all their annual

inspections have checked out fine. The

inspection is performed by the gearbox manufacture with the cement company

personnel.

In another example, they had a mechanical

problem with a gearbox that had been in the plant for a number of

years. It had lost an upper thrust

bearing and damaged the boiler box.

When the company went on to a refit, it saw a significant decrease in

amperage when the gearbox ran on oil and one of the Petron PlusTM Formula

7

T&GB Supplement mixture, even though the mechanical work was incomplete. The improvement in performance was even

greater once the unit had been repaired.

As a

result of this experience, they decided to use the Petron PlusTM Formula

7

T&GB Supplement in every critical gearbox, and since they are a

seven-day-a-week, 365 day-a-year operations, and shut down only for

emergencies, this practice has helped them avoid unnecessary downtime.

They

have also used the Petron PlusTM Formula 7 T&GB on their rotary kiln. The kiln is about 14-½ feet in diameter

and 350 feet long, making it among the largest pieces of moving equipment

used in any manufacturing operation.

To thoroughly expose the raw materials to the high temperatures, the

kiln rotates at approximately 120-130 revolutions per hour. The rotary kiln rests on three main

piers, with two bearings at each pier supporting the kiln as it rotates. The supports at piers 1 and 2 are 21”

diameter shelves running in 21” bearings.

Pier 2 is a 26” shelf running in a 26” bearing. All the bearings are heavily loaded as

the raw material moves slowly through the kiln.

The

bearings are inspected on an annual basis. They have seen an improved finish on the brass bearing surface and the

shaft since they began using the Petron

PlusTM Formula 7 T&GB.

The thrust plates are cleaner and better polished, and the overall

bearing condition has improved.

A raw

mill I.D. fan is another application.

This fan ran with a slightly scored shaft and pulled babbit for two

months after maintenance personnel made an emergency application of the Petron PlusTM Formula

7

Product into the lube system to try and hold off further deterioration and

a sudden unscheduled shutdown. At a programmed time, the bearing was

changed and the shaft left in place.

The shaft was found to be sooth and undamaged from the day that the

oil had been fortified with the supplement.

They

also found one of the Petron PlusTM Formula 7 T&GB to be a great benefit to the

plant’s clinker production and cooling operation. In the production process, a mixture of finely ground

limestone, clay and gypsum, heated to about 2700°F, emerges as clinker and

drops into a cooler, where it is cooled by a series of eight induced draft

fans. An automated lubricating

system feeds grease to the 2 fan bearings at preset intervals. The bearings are expensive; however, the

cost of the bearings failure and replacement is only part of the

problem. Any time that a bearing fails

it shuts down the main clinker production line. As a result, cost reduction is less a matter of bearing replacement

than it is of reducing the amount of downtime.

“Since

they began using one of the Petron PlusTM Formula 7 T&GB on their cooler fans and

bearings, the replacement rate has dropped by at least 50%”, their maintenance

supervisor reported. “We had a record of years of

bearing replacement, so that when we changed the lubricant and the bearing

replacement rate declined, the improvement was obvious.”

In the

automotive racing world the reports have been just as dramatic. One race team reported a four

4%) percent increase in horse power from 1,290 H.P. to 1,340 to 1,340 H.P.

on a dyno test after one of the Petron

PlusTM Formula 7 Product was added to the

engine oil, this was

done after they had made

all their adjustments and settings.

The above picture resembles the metal

surfaces in an engine. Solids only

protect your engine on minimum levels.

The Petron Plus Formula 7 technology literally impregnates the metal

surfaces of your engine, the same holds true when applied to gear oils in

gearboxes, and hydraulic fluids, etc.

A

highly respected independent research and testing laboratory in San Antonio,

Texas, regularly conducts competitive performance tests on the Petron Plus Formula 7 products.

These

test are the most stringent for a products of this type, and consistent

results demonstrate that they exceed the performance of all competitors and

significantly enhanced the performance characteristics of the high quality

lubricants.

With

the price of crude oil a few months ago over one hundred forty US dollars

per barrel, the price of chemicals and lubricants surely will be

affected. But, with quality and

high productivity back in style in the US, manufacturers cannot afford to

slow down or shut down for the lack of adequate chemicals or

lubricants. Neither can they stand

to lose any chance of a competitive edge over growing foreign industries.

The Petron

PlusTM Formula

7 Products helps reduce

emission, smog, thereby keeps the environment cleaner.

The Petron PlusTM Formula 7 Products helps to reduces

maintenance downtime, labor, and parts replacement costs.

Helps to increase overall efficiency and productivity of operating

equipment. It also increases the life of

the base lubricant thereby decreases drain intervals.

Most users realize immediate multiple benefits

when the Petron PlusTM

Formula 7 Products are

introduced into a broad range of machinery, equipment, or vehicle

applications:

- Helps substantial to increase

equipment-operating life, with consistent "like new" performance.

- Helps to decrease energy or fuel

required for normal equipment operation.

- Helps to increase horsepower and

performance output, even under high load, high performance demands.

- Helps to decrease operating

temperatures in gearboxes, bearing housing and engines.

- Helps to keep lubricant

contamination in suspension, thereby increasing lubricant life.

- Helps increase the ability of

base lubricants to prevent rust and corrosion, resist oxidation.

- Helps reduce emissions, smog,

thereby keeping the environment cleaner.

- Helps to significantly reduce

maintenance downtime, labor, and parts replacement costs.

- Helps to increase overall

efficiency and productivity of operating equipment.

- Helps to increase base lubricant

life, thereby decrease drain intervals.

- Helps to increase profitability

for plants operating the equipment and utilizing Petron Plus Products.

To stay competitive, fleets, and

industries must look to both the oil giants of the world and to small,

specialty lubricant, additive and/or chemical manufacturers for solutions

to their needs. Old-line additive

manufactures--as well as newer companies--must focus their total resources

on the research, development and implementation of proprietary chemical

packages. They must address issues

concerning additives, metal treatments, lubrication, and fuel supplements

that are designed specifically for future fleet, and industrial

applications.

The world’s “new-generation” of lubricants, and fuel-additive packages are

already here and are available in supplements, or already blended into

fully formulated lubricants.

They range from fully-formulated synthetic,

non-synthetic and partial synthetic motor oils, ATF's, automotive gear oils,

industrial gear oils, hydraulic fluids, compressor oils, natural gas engine

oils, automotive a/c lubes, turbine oils, refrigeration oils, natural gas

compressor oils, aerosol products, greases, metalworking fluids, to EPA

registered gasoline additives and diesel fuel additives, industrial

cleaning products, and automotive and fleet cooling systems cleaners and

corrosion inhibitors & treatments. Some of these products have H-1 and

H-2 food grade approval by USDA and NSF.

The company also has a product line that meets certain Military

Specifications. As well as a full

range of Bio-Degradable products, to our Petron PlusTM Formula

7 line of Supplement

Products.

We hope this information helps. Should you have any

questions or require specific information about any of our products,

please, do not hesitate to call our Product and Service Center Hotline at

620/663-1800, or you may write to me at the address shown above, or you may

fax me at 620/663-8560.

Thank you for your consideration in Petron

PlusTM

Formula 7, Petronomics® Formula 7 and PPX products, and your

obvious concern for quality lubricants

PETRON PLUSTM,

PETRONOMICS® and PPX Formula 7® products are “Guaranteed...

because we value your investment as much as you do!”

|